>back to Chapters of Fluid Mechanics for MAP

>back to Chapters of Microfluid Mechanics

Flows completely bounded by solid surfaces are called internal flows. External flows are flows over bodies immersed in an unbounded fluid[ 1]

Internal flows might be laminar or turbulent. The state of the flow regime is dependent on Re. There might be an analytical solution for laminar flows but not for turbulent flows.

Flows through pipes, ducts, nozzles, diffusers, valves and fittings are examples of internal flows.

Flow around an aircraft is classified under external flows. Flow around a car is classified under external flows.

At fully developed state the velocity profile becomes parabolic for laminar flow. The average velocity at any cross section is:

U

¯

=

U

0

=

V

=

1

A

∫

A

r

e

a

U

1

d

A

{\displaystyle {\bar {U}}=U_{0}=V={\frac {1}{A}}\int _{Area}{U_{1}dA}}

For the same flow value i.e.

U

0

{\displaystyle U_{0}}

The reason is the turbulent eddies, which causes more momentum loss to the wall i.e. higher velocity gradients close to the wall. Note that such a direct comparison is only valid at the same

R

e

=

U

0

D

ν

{\displaystyle Re={\frac {U_{0}D}{\nu }}}

Velocity profiles for laminar (upper) and turbulent (lower) states at the same mass flow rate

Signal measured by a hot-wire at a center of a pipe during transition showing the developement of transitional structures along the pipe at different Reynolds numbers[ 2] [ 3]

Development of velocity profile in a pipe with increasing Reynolds number

Flow between two plates

D

{\displaystyle D}

x

3

{\displaystyle x_{3}}

x

2

{\displaystyle x_{2}}

x

1

{\displaystyle x_{1}}

x

1

=

L

e

{\displaystyle x_{1}=L_{e}}

x

1

{\displaystyle x_{1}}

∂

U

i

∂

x

1

=

0

→

∂

τ

i

j

∂

x

1

=

0

{\displaystyle {\frac {\partial U_{i}}{\partial x_{1}}}=0\rightarrow {\frac {\partial \tau _{ij}}{\partial x_{1}}}=0}

x

3

{\displaystyle x_{3}}

U

3

=

0

,

∂

U

i

∂

x

3

=

0

,

∂

τ

i

j

∂

x

3

=

0

,

∂

P

∂

x

3

=

0

,

{\displaystyle U_{3}=0\ ,\ {\frac {\partial U_{i}}{\partial x_{3}}}=0\ ,\ {\frac {\partial \tau _{ij}}{\partial x_{3}}}=0\ ,\ {\frac {\partial P}{\partial x_{3}}}=0,}

U

2

=

U

3

=

0

{\displaystyle U_{2}=U_{3}=0}

U

1

=

U

1

(

x

2

)

,

τ

i

j

=

τ

i

j

(

x

2

)

.

{\displaystyle U_{1}=U_{1}(x_{2})\ ,\ \tau _{ij}=\tau _{ij}(x_{2}).}

[ 4]

L

e

p

i

p

e

D

=

[

(

0.619

)

1.6

+

(

0.0567

R

e

)

1.6

]

1

1.6

{\displaystyle {\frac {Le_{pipe}}{D}}=\left[(0.619)^{1.6}+(0.0567Re)^{1.6}\right]^{\frac {1}{1.6}}}

L

e

c

h

a

n

n

e

l

D

=

[

(

0.631

)

1.6

+

(

0.0442

R

e

)

1.6

]

1

1.6

{\displaystyle {\frac {Le_{channel}}{D}}=\left[(0.631)^{1.6}+(0.0442Re)^{1.6}\right]^{\frac {1}{1.6}}}

Fully Developed Laminar Flow Between Infinite Parallel Plates [ edit | edit source ] Fully developed flow in a channel with an infinite depth Consider the fully developed laminar flow between two infinite plates.

Consider the continuity equation and momentum equation in

x

1

{\displaystyle x_{1}}

Continuity Equation

∂

ρ

∂

t

⏟

=

0

+

∂

ρ

U

i

∂

x

i

=

0

⟶

ρ

=

c

s

t

.

∂

U

i

∂

x

i

=

0

{\displaystyle \underbrace {\frac {\partial \rho }{\partial t}} _{=0}+{\frac {\partial \rho U_{i}}{\partial x_{i}}}=0\ {\stackrel {\rho =cst.}{\longrightarrow }}\ {\frac {\partial U_{i}}{\partial x_{i}}}=0}

∂

U

1

∂

x

1

=

0

{\displaystyle {\frac {\partial U_{1}}{\partial x_{1}}}=0}

∂

U

3

∂

x

3

=

0

→

∂

U

2

∂

x

2

=

0

{\displaystyle {\frac {\partial U_{3}}{\partial x_{3}}}=0\rightarrow {\frac {\partial U_{2}}{\partial x_{2}}}=0}

U

2

{\displaystyle \ U_{2}}

U

2

=

c

o

n

s

t

a

n

t

{\displaystyle \ U_{2}=constant}

As

U

2

{\displaystyle \ U_{2}}

U

2

(

x

2

)

=

0

{\displaystyle \ U_{2}(x_{2})=0}

Momentum Equation in j-direction

ρ

∂

U

j

∂

t

⏟

=

0

S

t

e

a

d

y

+

ρ

U

i

∂

U

j

∂

x

i

=

−

∂

P

∂

x

j

+

ρ

g

j

+

∂

τ

i

j

∂

x

i

{\displaystyle \underbrace {\rho {\frac {\partial U_{j}}{\partial t}}} _{=0\ Steady}+\rho U_{i}{\frac {\partial U_{j}}{\partial x_{i}}}=-{\frac {\partial P}{\partial x_{j}}}+\rho g_{j}+{\frac {\partial \tau _{ij}}{\partial x_{i}}}}

in

x

1

{\displaystyle x_{1}}

g

1

=

0

{\displaystyle g_{1}=0}

ρ

U

i

∂

U

1

∂

x

i

⏟

A

=

−

∂

P

∂

x

1

+

∂

τ

i

1

∂

x

i

⏟

B

{\displaystyle \underbrace {\rho U_{i}{\frac {\partial U_{1}}{\partial x_{i}}}} _{A}=-{\frac {\partial P}{\partial x_{1}}}+\underbrace {\frac {\partial \tau _{i1}}{\partial x_{i}}} _{B}}

ρ

U

i

∂

U

1

∂

x

i

=

ρ

[

U

1

∂

U

1

∂

x

1

⏟

=

0

F

u

l

l

y

−

d

e

v

e

l

o

p

e

d

+

U

2

⏟

=

0

∂

U

1

∂

x

2

+

U

3

⏟

=

0

f

u

l

l

y

−

d

e

v

e

l

o

p

e

d

2

D

∂

U

1

∂

x

3

⏟

=

0

2

D

]

=

0

{\displaystyle \rho U_{i}{\frac {\partial U_{1}}{\partial x_{i}}}=\rho \left[U_{1}\underbrace {\frac {\partial U_{1}}{\partial x_{1}}} _{=0\ Fully-developed}+\underbrace {U_{2}} _{=0}{\frac {\partial U_{1}}{\partial x_{2}}}+\underbrace {U_{3}} _{=0\ fully-developed\ 2D}\underbrace {\frac {\partial U_{1}}{\partial x_{3}}} _{=0\ 2D}\right]=0}

∂

τ

i

1

∂

x

i

=

∂

τ

11

∂

x

1

⏟

=

0

f

u

l

l

y

−

d

e

v

.

+

∂

τ

21

∂

x

2

+

∂

τ

31

∂

x

3

⏟

=

0

2

D

=

∂

τ

τ

21

∂

x

2

=

d

τ

21

d

x

2

{\displaystyle {\frac {\partial \tau _{i1}}{\partial x_{i}}}=\underbrace {\frac {\partial \tau _{11}}{\partial x_{1}}} _{=0\ fully-dev.}+{\frac {\partial \tau _{21}}{\partial x_{2}}}+\underbrace {\frac {\partial \tau _{31}}{\partial x_{3}}} _{=0\ 2D}={\frac {\partial \tau _{\tau _{21}}}{\partial x_{2}}}={\frac {d\tau _{21}}{dx_{2}}}}

τ

21

=

τ

21

(

x

2

)

{\displaystyle \tau _{21}=\tau _{21}(x_{2})}

x

1

{\displaystyle x_{1}}

0

=

−

∂

P

∂

x

1

+

d

τ

21

d

x

2

{\displaystyle 0=-{\frac {\partial P}{\partial x_{1}}}+{\frac {d\tau _{21}}{dx_{2}}}}

x

1

{\displaystyle x_{1}}

x

2

{\displaystyle x_{2}}

∂

P

∂

x

1

=

d

τ

21

d

x

2

{\displaystyle {\frac {\partial P}{\partial x_{1}}}={\frac {d\tau _{21}}{dx_{2}}}}

τ

21

{\displaystyle \tau _{21}}

x

1

{\displaystyle x_{1}}

x

2

{\displaystyle x_{2}}

τ

i

j

=

μ

(

∂

U

i

∂

x

j

+

∂

U

j

∂

x

i

)

+

2

3

δ

i

j

μ

∂

U

k

∂

x

k

{\displaystyle \tau _{ij}=\mu \left({\frac {\partial U_{i}}{\partial x_{j}}}+{\frac {\partial U_{j}}{\partial x_{i}}}\right)+{\frac {2}{3}}\delta _{ij}\mu {\frac {\partial U_{k}}{\partial x_{k}}}}

τ

21

=

μ

(

∂

U

2

∂

x

1

⏟

=

0

+

∂

U

1

∂

x

2

)

+

0

{\displaystyle \tau _{21}=\mu \left(\underbrace {\frac {\partial U_{2}}{\partial x_{1}}} _{=0}+{\frac {\partial U_{1}}{\partial x_{2}}}\right)+0}

τ

21

=

μ

∂

U

1

∂

x

2

since,

U

1

=

U

1

(

x

2

)

τ

21

=

μ

d

U

1

d

x

2

{\displaystyle \tau _{21}=\mu {\frac {\partial U_{1}}{\partial x_{2}}}\ {\text{since,}}\ U_{1}=U_{1}(x_{2})\ \tau _{21}=\mu {\frac {dU_{1}}{dx_{2}}}}

Thus the momentum equation reads:

∂

P

∂

x

1

=

μ

d

2

U

1

d

x

2

2

{\displaystyle {\frac {\partial P}{\partial x_{1}}}=\mu {\frac {d^{2}U_{1}}{dx_{2}^{2}}}}

Treatment of channel flow with the RTT approach The momentum equation in

x

1

{\displaystyle x_{1}}

F

S

1

+

F

B

1

⏟

=

0

=

∂

∂

t

∫

C

V

ρ

U

1

d

V

⏟

=

0

+

∫

C

S

U

1

ρ

U

i

n

i

d

A

⏟

=

0

f

u

l

l

y

−

d

e

v

.

{\displaystyle F_{S1}+\underbrace {F_{B1}} _{=0}={\frac {\partial }{\partial t}}\underbrace {\int _{CV}\rho U_{1}dV} _{=0}+\underbrace {\int _{CS}U_{1}\rho U_{i}n_{i}dA} _{=0\ fully-dev.}}

F

S

1

=

0

{\displaystyle \displaystyle F_{S1}=0}

(

p

−

∂

P

∂

x

1

d

x

1

2

)

d

x

2

d

x

3

−

(

p

+

∂

P

∂

x

1

d

x

1

2

)

d

x

2

d

x

3

{\displaystyle \left(p-{\frac {\partial P}{\partial x_{1}}}{\frac {dx_{1}}{2}}\right)dx_{2}dx_{3}-\left(p+{\frac {\partial P}{\partial x_{1}}}{\frac {dx_{1}}{2}}\right)dx_{2}dx_{3}}

+

(

τ

21

+

d

x

2

2

∂

τ

21

∂

x

2

)

d

x

1

d

x

3

−

(

τ

21

−

d

x

2

2

∂

τ

21

∂

x

2

)

d

x

1

d

x

3

=

0

{\displaystyle +\left(\tau _{21}+{\frac {dx_{2}}{2}}{\frac {\partial \tau _{21}}{\partial x_{2}}}\right)dx_{1}dx_{3}-\left(\tau _{21}-{\frac {dx_{2}}{2}}{\frac {\partial \tau _{21}}{\partial x_{2}}}\right)dx_{1}dx_{3}=0}

−

∂

P

∂

x

1

d

V

+

∂

τ

21

∂

x

2

d

V

=

0

{\displaystyle -{\frac {\partial P}{\partial x_{1}}}dV+{\frac {\partial \tau _{21}}{\partial x_{2}}}dV=0}

−

∂

P

∂

x

1

+

∂

τ

21

∂

x

2

=

0

{\displaystyle -{\frac {\partial P}{\partial x_{1}}}+{\frac {\partial \tau _{21}}{\partial x_{2}}}=0}

∂

P

∂

x

1

=

μ

d

2

U

1

d

x

2

2

{\displaystyle {\frac {\partial P}{\partial x_{1}}}=\mu {\frac {d^{2}U_{1}}{dx_{2}^{2}}}}

x

2

=

0

→

U

1

=

0

{\displaystyle x_{2}=0\rightarrow U_{1}=0}

x

2

=

D

→

U

1

=

0

{\displaystyle x_{2}=D\rightarrow U_{1}=0}

Integrating the equation once results in a linear function of

x

2

{\displaystyle x_{2}}

μ

d

U

1

d

x

2

=

(

∂

P

∂

x

1

)

x

2

+

c

1

→

τ

21

=

(

∂

P

∂

x

1

)

x

2

+

c

1

{\displaystyle \mu {\frac {dU_{1}}{dx_{2}}}=\left({\frac {\partial P}{\partial x_{1}}}\right)x_{2}+c_{1}\rightarrow \tau _{21}=\left({\frac {\partial P}{\partial x_{1}}}\right)x_{2}+c_{1}}

U

1

=

1

2

μ

(

∂

P

∂

x

1

)

x

2

2

+

1

μ

c

1

x

2

+

c

2

{\displaystyle U_{1}={\frac {1}{2\mu }}\left({\frac {\partial P}{\partial x_{1}}}\right)x_{2}^{2}+{\frac {1}{\mu }}c_{1}x_{2}+c_{2}}

x

2

=

0

,

U

1

=

0

→

c

2

=

0

{\displaystyle x_{2}=0,\ U_{1}=0\rightarrow c_{2}=0}

x

2

=

D

,

U

1

=

0

→

c

1

=

−

1

2

(

∂

P

∂

x

1

)

D

{\displaystyle x_{2}=D,\ U_{1}=0\rightarrow c_{1}=-{\frac {1}{2}}\left({\frac {\partial P}{\partial x_{1}}}\right)D}

U

1

=

1

2

μ

(

∂

P

∂

x

1

x

2

2

)

−

1

2

μ

(

∂

P

∂

x

1

)

D

x

2

=

D

2

2

μ

(

∂

P

∂

x

1

)

[

(

x

2

D

)

2

−

(

x

2

D

)

]

{\displaystyle {\begin{array}{lll}U_{1}&=&{\frac {1}{2\mu }}\left({\frac {\partial P}{\partial x_{1}}}x_{2}^{2}\right)-{\frac {1}{2\mu }}\left({\frac {\partial P}{\partial x_{1}}}\right)D{x_{2}}\\&=&{\frac {D^{2}}{2\mu }}\left({\frac {\partial P}{\partial x_{1}}}\right)\left[\left({\frac {x_{2}}{D}}\right)^{2}-\left({\frac {x_{2}}{D}}\right)\right]\end{array}}}

Note that the velocity profile is parabolic!

The shear stress becomes:

τ

21

=

(

∂

P

∂

x

1

)

x

2

−

1

2

(

∂

P

∂

x

1

)

D

=

D

(

∂

P

∂

x

1

)

[

x

2

D

−

1

2

]

{\displaystyle {\begin{array}{lll}\tau _{21}&=&\left({\frac {\partial P}{\partial x_{1}}}\right)x_{2}-{\frac {1}{2}}\left({\frac {\partial P}{\partial x_{1}}}\right)D\\&=&D\left({\frac {\partial P}{\partial x_{1}}}\right)\left[{\frac {x_{2}}{D}}-{\frac {1}{2}}\right]\end{array}}}

x

2

{\displaystyle x_{2}}

x

2

{\displaystyle x_{2}}

τ

21

(

0

)

=

−

1

2

D

(

∂

P

∂

x

1

)

{\displaystyle \tau _{21}(0)=-{\frac {1}{2}}D\left({\frac {\partial P}{\partial x_{1}}}\right)}

τ

21

(

D

)

=

1

2

D

(

∂

P

∂

x

1

)

{\displaystyle \tau _{21}(D)={\frac {1}{2}}D\left({\frac {\partial P}{\partial x_{1}}}\right)}

Velocity and shear stress profiles in fully developed channel flow

τ

21

{\displaystyle \tau _{21}}

∂

U

1

∂

x

2

{\displaystyle {\frac {\partial U_{1}}{\partial x_{2}}}}

The volume flow rate is,

Q

=

∫

A

U

i

n

i

d

A

=

∫

0

D

U

1

w

d

x

2

{\displaystyle Q=\int _{A}U_{i}n_{i}dA=\int _{0}^{D}U_{1}wdx_{2}}

w

{\displaystyle w}

Thus the volume flow rate per depth

w

{\displaystyle w}

Q

w

=

∫

0

D

1

2

μ

(

∂

P

∂

x

1

)

(

x

2

−

D

x

2

)

d

x

2

{\displaystyle {\frac {Q}{w}}=\int _{0}^{D}{\frac {1}{2\mu }}\left({\frac {\partial P}{\partial x_{1}}}\right)\left(x^{2}-D{x_{2}}\right)dx_{2}}

Q

w

=

−

1

12

μ

(

∂

P

∂

x

1

)

D

3

{\displaystyle {\frac {Q}{w}}=-{\frac {1}{12\mu }}\left({\frac {\partial P}{\partial x_{1}}}\right)D^{3}}

∂

P

∂

x

1

{\displaystyle {\frac {\partial P}{\partial x_{1}}}}

L

{\displaystyle L}

∂

P

∂

x

1

=

p

2

−

p

1

L

=

−

Δ

P

L

{\displaystyle {\frac {\partial P}{\partial x_{1}}}={\frac {p_{2}-p_{1}}{L}}={\frac {-\Delta P}{L}}}

Where

Δ

P

{\displaystyle \Delta P}

Q

w

=

−

1

12

μ

(

−

Δ

P

L

)

D

3

=

D

3

12

μ

L

Δ

P

{\displaystyle {\frac {Q}{w}}=-{\frac {1}{12\mu }}\left({\frac {-\Delta P}{L}}\right)D^{3}={\frac {D^{3}}{12\mu L}}\Delta P}

Δ

P

=

Q

l

12

μ

L

D

3

{\displaystyle \Delta P={\frac {Q}{l}}{\frac {12\mu L}{D^{3}}}}

The average velocity

U

¯

{\displaystyle {\bar {U}}}

U

¯

=

U

0

=

Q

A

=

Q

w

D

=

−

1

12

μ

(

∂

P

∂

x

1

)

D

3

w

w

D

=

−

1

12

μ

(

∂

P

∂

x

1

)

D

2

{\displaystyle {\bar {U}}=U_{0}={\frac {Q}{A}}={\frac {Q}{wD}}=-{\frac {1}{12\mu }}\left({\frac {\partial P}{\partial x_{1}}}\right){\frac {D^{3}w}{wD}}=-{\frac {1}{12\mu }}\left({\frac {\partial P}{\partial x_{1}}}\right)D^{2}}

d

U

1

d

x

2

=

0

=

D

2

2

μ

(

∂

P

∂

x

1

)

(

2

x

2

D

2

−

1

D

)

{\displaystyle {\frac {dU_{1}}{dx_{2}}}=0={\frac {D^{2}}{2\mu }}\left({\frac {\partial P}{\partial x_{1}}}\right)\left({\frac {2x_{2}}{D^{2}}}-{\frac {1}{D}}\right)}

x

2

=

D

2

{\displaystyle x_{2}={\frac {D}{2}}}

U

1

=

U

1

m

a

x

{\displaystyle U_{1}=U_{1max}}

U

1

(

D

2

)

=

U

1

m

a

x

=

−

1

8

μ

(

∂

P

∂

x

1

)

D

2

=

3

2

U

¯

{\displaystyle U_{1}\left({\frac {D}{2}}\right)=U_{1max}=-{\frac {1}{8\mu }}\left({\frac {\partial P}{\partial x_{1}}}\right)D^{2}={\frac {3}{2}}{\bar {U}}}

U

¯

{\displaystyle {\overline {U}}}

U

1

m

a

x

{\displaystyle U_{1max}}

U

1

=

−

4

U

1

m

a

x

[

(

x

2

D

)

2

−

(

x

2

D

)

]

=

−

6

U

¯

[

(

x

2

D

)

2

−

(

x

2

D

)

]

{\displaystyle {\begin{array}{lll}U_{1}&=&-4U_{1max}\left[\left({\frac {x_{2}}{D}}\right)^{2}-\left({\frac {x_{2}}{D}}\right)\right]\\&=&-6{\overline {U}}\left[\left({\frac {x_{2}}{D}}\right)^{2}-\left({\frac {x_{2}}{D}}\right)\right]\end{array}}}

Same problem can be solved by using moving plates.

Flow through the gap between a cylindrical piston and the surrounding wall

ρ

{\displaystyle \rho }

k

g

m

3

{\displaystyle {\frac {kg}{m^{3}}}}

μ

{\displaystyle \mu }

k

g

m

s

e

c

{\displaystyle {\frac {kg}{m\ sec}}}

(

L

a

=

3000

)

{\displaystyle \left({\frac {L}{a}}=3000\right)}

D

a

=

25

0

,

005

{\displaystyle {\frac {D}{a}}={\frac {25}{0,005}}}

w

=

π

⋅

D

{\displaystyle w=\pi \cdot D}

Q

w

=

a

3

Δ

P

12

μ

L

{\displaystyle {\frac {Q}{w}}={\frac {a^{3}\Delta P}{12\mu L}}}

Q

=

a

3

Δ

P

12

μ

L

π

D

=

(

0.005

⋅

10

−

3

)

3

12

∗

(

0.018

)

∗

15

⋅

10

−

3

∗

(

20

−

1

)

⋅

10

−

6

∗

π

∗

25

⋅

10

−

3

{\displaystyle Q={\frac {a^{3}\Delta P}{12\mu L}}\pi D={\frac {(0.005\cdot 10^{-3})^{3}}{12*(0.018)*15\cdot 10^{-3}}}*(20-1)\cdot 10^{-6}*\pi *25\cdot 10^{-3}}

Q

=

57.6

⋅

10

−

9

m

3

s

=

57.6

m

m

3

s

e

c

{\displaystyle Q=57.6\cdot 10^{-9}{\frac {m^{3}}{s}}=57.6{\frac {mm^{3}}{sec}}}

U

¯

=

Q

A

=

Q

π

D

a

=

0.147

m

s

e

c

{\displaystyle {\bar {U}}={\frac {Q}{A}}={\frac {Q}{\pi D\ a}}=0.147{\frac {m}{sec}}}

R

e

=

ρ

U

¯

a

μ

=

932

∗

0.147

∗

0.005

⋅

10

−

3

0.018

=

0.0375

{\displaystyle Re={\frac {\rho {\bar {U}}a}{\mu }}={\frac {932*0.147*0.005\cdot 10^{-3}}{0.018}}=0.0375}

<<

1800

{\displaystyle <<1800}

μ

A

{\displaystyle \displaystyle \mu _{A}}

ρ

A

{\displaystyle \displaystyle \rho _{A}}

m

˙

A

{\displaystyle \displaystyle {\dot {m}}_{A}}

μ

B

{\displaystyle \displaystyle \mu _{B}}

ρ

B

{\displaystyle \displaystyle \rho _{B}}

m

˙

B

{\displaystyle \displaystyle {\dot {m}}_{B}}

τ

21

{\displaystyle \displaystyle \tau _{21}}

d

τ

21

A

d

x

2

=

d

Π

d

x

1

{\displaystyle {\frac {d\tau _{21}^{A}}{dx_{2}}}={\frac {d\Pi }{dx_{1}}}}

d

τ

21

B

d

x

2

=

d

Π

d

x

1

{\displaystyle {\frac {d\tau _{21}^{B}}{dx_{2}}}={\frac {d\Pi }{dx_{1}}}}

With

τ

21

=

μ

d

U

1

d

x

2

{\displaystyle \tau _{21}=\mu {\frac {dU_{1}}{dx_{2}}}}

d

2

U

1

A

d

x

2

=

1

μ

A

d

Π

d

x

1

{\displaystyle {\frac {d^{2}U_{1}^{A}}{dx_{2}}}={\frac {1}{\mu _{A}}}{\frac {d\Pi }{dx_{1}}}}

d

2

U

1

B

d

x

2

=

1

μ

B

d

Π

d

x

1

{\displaystyle {\frac {d^{2}U_{1}^{B}}{dx_{2}}}={\frac {1}{\mu _{B}}}{\frac {d\Pi }{dx_{1}}}}

τ

21

A

=

d

Π

d

x

1

x

2

+

C

1

A

{\displaystyle \tau _{21}^{A}={\frac {d\Pi }{dx_{1}}}x_{2}+C_{1}^{A}}

τ

21

B

=

d

Π

d

x

1

x

2

+

C

1

B

{\displaystyle \tau _{21}^{B}={\frac {d\Pi }{dx_{1}}}x_{2}+C_{1}^{B}}

τ

21

A

(

x

2

=

0

)

=

τ

21

B

(

x

2

=

0

)

{\displaystyle \tau _{21}^{A}(x_{2}=0)=\tau _{21}^{B}(x_{2}=0)}

C

1

A

=

C

1

B

=

C

1

{\displaystyle C_{1}^{A}=C_{1}^{B}=C_{1}}

U

1

A

=

1

2

μ

A

d

Π

d

x

1

x

2

2

+

C

1

μ

A

x

2

+

C

2

A

{\displaystyle U_{1}^{A}={\frac {1}{2\mu _{A}}}{\frac {d\Pi }{dx_{1}}}x_{2}^{2}+{\frac {C_{1}}{\mu _{A}}}x_{2}+C_{2}^{A}}

U

1

B

=

1

2

μ

B

d

Π

d

x

1

x

2

2

+

C

1

μ

B

x

2

+

C

2

B

{\displaystyle U_{1}^{B}={\frac {1}{2\mu _{B}}}{\frac {d\Pi }{dx_{1}}}x_{2}^{2}+{\frac {C_{1}}{\mu _{B}}}x_{2}+C_{2}^{B}}

U

1

A

(

x

2

=

0

)

=

U

1

B

(

x

2

=

0

)

{\displaystyle U_{1}^{A}(x_{2}=0)=U_{1}^{B}(x_{2}=0)}

C

2

A

≠

C

2

B

{\displaystyle C_{2}^{A}\neq C_{2}^{B}}

C

2

A

=

C

2

B

=

C

2

{\displaystyle C_{2}^{A}=C_{2}^{B}=C_{2}}

x

2

=

−

D

→

U

1

A

=

0

{\displaystyle x_{2}=-D\ \rightarrow \ \ U_{1}^{A}=0}

0

=

d

Π

d

x

1

1

2

μ

A

D

2

−

C

1

D

μ

A

+

C

2

{\displaystyle 0={\frac {d\Pi }{dx_{1}}}{\frac {1}{2\mu _{A}}}D^{2}-{\frac {C_{1}D}{\mu _{A}}}+C_{2}}

x

2

=

+

D

→

U

1

B

=

0

{\displaystyle x_{2}=+D\ \rightarrow \ \ U_{1}^{B}=0}

0

=

d

Π

d

x

1

1

2

μ

B

D

2

+

C

1

D

μ

B

+

C

2

{\displaystyle 0={\frac {d\Pi }{dx_{1}}}{\frac {1}{2\mu _{B}}}D^{2}+{\frac {C_{1}D}{\mu _{B}}}+C_{2}}

Therefore we obtain for the velocity distribution in the fluids A and B:

U

1

A

=

−

D

2

2

μ

A

d

Π

d

x

1

[

+

2

μ

A

(

μ

A

+

μ

B

)

+

(

μ

A

−

μ

B

μ

A

+

μ

B

)

(

x

2

D

)

−

(

x

2

D

)

2

]

{\displaystyle U_{1}^{A}=-{\frac {D^{2}}{2\mu _{A}}}{\frac {d\Pi }{dx_{1}}}\left[+{\frac {2\mu _{A}}{(\mu _{A}+\mu _{B})}}+\left({\frac {\mu _{A}-\mu _{B}}{\mu _{A}+\mu _{B}}}\right)\left({\frac {x_{2}}{D}}\right)-\left({\frac {x_{2}}{D}}\right)^{2}\right]\ \ \ \ \ }

U

1

B

=

−

D

2

2

μ

B

d

Π

d

x

1

[

+

2

μ

B

(

μ

A

+

μ

B

)

+

(

μ

A

−

μ

B

μ

A

+

μ

B

)

(

x

2

D

)

−

(

x

2

D

)

2

]

{\displaystyle U_{1}^{B}=-{\frac {D^{2}}{2\mu _{B}}}{\frac {d\Pi }{dx_{1}}}\left[+{\frac {2\mu _{B}}{(\mu _{A}+\mu _{B})}}+\left({\frac {\mu _{A}-\mu _{B}}{\mu _{A}+\mu _{B}}}\right)\left({\frac {x_{2}}{D}}\right)-\left({\frac {x_{2}}{D}}\right)^{2}\right]}

τ

21

=

D

d

Π

d

x

1

[

(

x

2

D

)

−

1

2

(

μ

A

−

μ

B

μ

A

+

μ

B

)

]

{\displaystyle \tau _{21}=D{\frac {d\Pi }{dx_{1}}}\left[\left({\frac {x_{2}}{D}}\right)-{\frac {1}{2}}\left({\frac {\mu _{A}-\mu _{B}}{\mu _{A}+\mu _{B}}}\right)\right]}

μ

A

=

μ

B

{\displaystyle \displaystyle \mu _{A}=\mu _{B}}

U

1

=

−

D

2

2

μ

A

d

Π

d

x

1

[

1

−

(

x

2

D

)

2

]

{\displaystyle U_{1}={\frac {-D^{2}}{2\mu _{A}}}{\frac {d\Pi }{dx_{1}}}\left[1-\left({\frac {x_{2}}{D}}\right)^{2}\right]}

τ

21

=

D

d

Π

d

x

1

(

x

2

D

)

{\displaystyle \tau _{21}=D{\frac {d\Pi }{dx_{1}}}\left({\frac {x_{2}}{D}}\right)}

τ

21

{\displaystyle \displaystyle \tau _{21}}

τ

21

=

0

{\displaystyle \displaystyle \tau _{21}=0}

μ

A

≠

μ

B

{\displaystyle \mu _{A}\neq \mu _{B}}

τ

21

=

0

{\displaystyle \displaystyle \tau _{21}=0}

x

2

(

U

1

m

a

x

)

=

D

2

(

μ

A

−

μ

B

μ

A

+

μ

B

)

{\displaystyle x_{2}(U_{1max})={\frac {D}{2}}\left({\frac {\mu _{A}-\mu _{B}}{\mu _{A}+\mu _{B}}}\right)}

τ

W

B

=

D

2

d

Π

d

x

1

[

μ

A

+

3

μ

B

μ

A

+

μ

B

]

{\displaystyle \tau _{W}^{B}={\frac {D}{2}}{\frac {d\Pi }{dx_{1}}}\left[{\frac {\mu _{A}+3\mu _{B}}{\mu _{A}+\mu _{B}}}\right]}

τ

W

A

=

−

D

2

d

Π

d

x

1

[

3

μ

A

+

μ

B

μ

A

+

μ

B

]

{\displaystyle \tau _{W}^{A}=-{\frac {D}{2}}{\frac {d\Pi }{dx_{1}}}\left[{\frac {3\mu _{A}+\mu _{B}}{\mu _{A}+\mu _{B}}}\right]}

U

~

1

A

=

−

D

2

12

μ

A

d

Π

d

x

1

(

7

μ

A

+

μ

B

μ

A

+

μ

B

)

{\displaystyle {\tilde {U}}_{1}^{A}=-{\frac {D^{2}}{12\mu _{A}}}{\frac {d\Pi }{dx_{1}}}\left({\frac {7\mu _{A}+\mu _{B}}{\mu _{A}+\mu _{B}}}\right)}

U

~

1

B

=

−

D

2

12

μ

B

d

Π

d

x

1

(

μ

A

+

7

μ

B

μ

A

+

μ

B

)

{\displaystyle {\tilde {U}}_{1}^{B}=-{\frac {D^{2}}{12\mu _{B}}}{\frac {d\Pi }{dx_{1}}}\left({\frac {\mu _{A}+7\mu _{B}}{\mu _{A}+\mu _{B}}}\right)}

m

˙

A

=

B

D

U

~

1

A

{\displaystyle {\dot {m}}_{A}=BD{\tilde {U}}_{1}^{A}}

m

˙

B

=

B

D

U

~

1

B

{\displaystyle {\dot {m}}_{B}=BD{\tilde {U}}_{1}^{B}}

A change of variables on the Cartesian equations will yield[ 5] r ,

ϕ

{\displaystyle \phi }

z directions:

r

:

ρ

(

∂

u

r

∂

t

+

u

r

∂

u

r

∂

r

+

u

ϕ

r

∂

u

r

∂

ϕ

+

u

x

∂

u

r

∂

x

−

u

ϕ

2

r

)

=

−

∂

p

∂

r

+

μ

[

1

r

∂

∂

r

(

r

∂

u

r

∂

r

)

+

1

r

2

∂

2

u

r

∂

ϕ

2

+

∂

2

u

r

∂

x

2

−

u

r

r

2

−

2

r

2

∂

u

ϕ

∂

ϕ

]

+

ρ

g

r

{\displaystyle r:\;\;\rho \left({\frac {\partial u_{r}}{\partial t}}+u_{r}{\frac {\partial u_{r}}{\partial r}}+{\frac {u_{\phi }}{r}}{\frac {\partial u_{r}}{\partial \phi }}+u_{x}{\frac {\partial u_{r}}{\partial x}}-{\frac {u_{\phi }^{2}}{r}}\right)=-{\frac {\partial p}{\partial r}}+\mu \left[{\frac {1}{r}}{\frac {\partial }{\partial r}}\left(r{\frac {\partial u_{r}}{\partial r}}\right)+{\frac {1}{r^{2}}}{\frac {\partial ^{2}u_{r}}{\partial \phi ^{2}}}+{\frac {\partial ^{2}u_{r}}{\partial x^{2}}}-{\frac {u_{r}}{r^{2}}}-{\frac {2}{r^{2}}}{\frac {\partial u_{\phi }}{\partial \phi }}\right]+\rho g_{r}}

ϕ

:

ρ

(

∂

u

ϕ

∂

t

+

u

r

∂

u

ϕ

∂

r

+

u

ϕ

r

∂

u

ϕ

∂

ϕ

+

u

x

∂

u

ϕ

∂

x

+

u

r

u

ϕ

r

)

=

−

1

r

∂

p

∂

ϕ

+

μ

[

1

r

∂

∂

r

(

r

∂

u

ϕ

∂

r

)

+

1

r

2

∂

2

u

ϕ

∂

ϕ

2

+

∂

2

u

ϕ

∂

z

2

+

2

r

2

∂

u

r

∂

ϕ

−

u

ϕ

r

2

]

+

ρ

g

ϕ

{\displaystyle \phi :\;\;\rho \left({\frac {\partial u_{\phi }}{\partial t}}+u_{r}{\frac {\partial u_{\phi }}{\partial r}}+{\frac {u_{\phi }}{r}}{\frac {\partial u_{\phi }}{\partial \phi }}+u_{x}{\frac {\partial u_{\phi }}{\partial x}}+{\frac {u_{r}u_{\phi }}{r}}\right)=-{\frac {1}{r}}{\frac {\partial p}{\partial \phi }}+\mu \left[{\frac {1}{r}}{\frac {\partial }{\partial r}}\left(r{\frac {\partial u_{\phi }}{\partial r}}\right)+{\frac {1}{r^{2}}}{\frac {\partial ^{2}u_{\phi }}{\partial \phi ^{2}}}+{\frac {\partial ^{2}u_{\phi }}{\partial z^{2}}}+{\frac {2}{r^{2}}}{\frac {\partial u_{r}}{\partial \phi }}-{\frac {u_{\phi }}{r^{2}}}\right]+\rho g_{\phi }}

x

:

ρ

(

∂

u

x

∂

t

+

u

r

∂

u

x

∂

r

+

u

ϕ

r

∂

u

x

∂

ϕ

+

u

x

∂

u

x

∂

x

)

=

−

∂

p

∂

x

+

μ

[

1

r

∂

∂

r

(

r

∂

u

x

∂

r

)

+

1

r

2

∂

2

u

x

∂

ϕ

2

+

∂

2

u

x

∂

x

2

]

+

ρ

g

x

.

{\displaystyle x:\;\;\rho \left({\frac {\partial u_{x}}{\partial t}}+u_{r}{\frac {\partial u_{x}}{\partial r}}+{\frac {u_{\phi }}{r}}{\frac {\partial u_{x}}{\partial \phi }}+u_{x}{\frac {\partial u_{x}}{\partial x}}\right)=-{\frac {\partial p}{\partial x}}+\mu \left[{\frac {1}{r}}{\frac {\partial }{\partial r}}\left(r{\frac {\partial u_{x}}{\partial r}}\right)+{\frac {1}{r^{2}}}{\frac {\partial ^{2}u_{x}}{\partial \phi ^{2}}}+{\frac {\partial ^{2}u_{x}}{\partial x^{2}}}\right]+\rho g_{x}.}

The continuity equation is:

∂

ρ

∂

t

+

1

r

∂

∂

r

(

ρ

r

u

r

)

+

1

r

∂

∂

ϕ

(

ρ

u

ϕ

)

+

∂

∂

x

(

ρ

u

x

)

=

0.

{\displaystyle {\frac {\partial \rho }{\partial t}}+{\frac {1}{r}}{\frac {\partial }{\partial r}}\left(\rho ru_{r}\right)+{\frac {1}{r}}{\frac {\partial }{\partial \phi }}\left(\rho u_{\phi }\right)+{\frac {\partial }{\partial x}}\left(\rho u_{x}\right)=0.}

Treatment of pipe flow with the RTT approach(with infinitesimal cylinder) It is possible to use the same mathematical treatment like before to find and understand the velocity profile for fully developed flow inside a pipe with diameter D and infinite length. To show the flexibility, the same solution for this problem will be approached via 3 different ways.

(i) Infinitesimal Cylinder at the center of the pipe

Applying the RTT to the infinitesimal cylindrical CV along the symmetry axis of horizontal pipe, in which the flow is fully developed, the conservation of mass and the transport side of the conservation of momentum equation drops. Only remaining term governing this kind of flow is the balance of the forces on the CV in

x

{\displaystyle x}

(

p

−

∂

P

∂

x

d

x

2

)

π

r

2

−

(

p

+

∂

P

∂

x

d

x

2

)

π

r

2

+

τ

r

x

2

π

r

d

x

=

0

{\displaystyle \left(p-{\frac {\partial P}{\partial x}}{\frac {dx}{2}}\right)\pi r^{2}-\left(p+{\frac {\partial P}{\partial x}}{\frac {dx}{2}}\right)\pi r^{2}+\tau _{r_{x}}2\pi rdx=0}

−

∂

P

∂

x

d

x

π

r

2

+

τ

r

x

2

π

r

d

x

=

0

{\displaystyle -{\frac {\partial P}{\partial x}}dx\pi r^{2}+\tau _{r_{x}}2\pi rdx=0}

τ

r

x

=

r

2

∂

P

∂

x

{\displaystyle \tau _{r_{x}}={\frac {r}{2}}{\frac {\partial P}{\partial x}}}

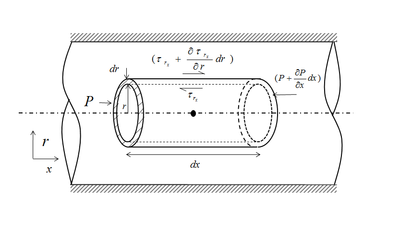

(ii) Infinitesimal thin hollow cylinder at the center

Treatment of pipe flow with the RTT approach(with infinitesimal hollow cylinder) This time the pressure and viscous force is considered for a concentric hollow cylinder with radius of R and infinitesimally small thickness dr and length dx(as shown in the image besides) along x-direction. Considering pressure term on the cross-section of cylinder

p

2

π

r

d

r

−

(

p

+

∂

P

∂

x

d

x

)

2

π

r

d

r

→

−

(

∂

P

∂

x

)

2

π

r

d

r

d

x

{\displaystyle p2\pi rdr-\left(p+{\frac {\partial P}{\partial x}}{dx}\right)2\pi rdr\rightarrow -\left({\frac {\partial P}{\partial x}}\right)2\pi rdrdx}

considering viscous shear stress on the surface of the cylinder

(

τ

r

x

+

∂

τ

r

x

∂

r

d

r

)

2

π

(

r

+

d

r

)

d

x

−

τ

r

x

2

π

r

d

x

{\displaystyle \left(\tau _{r_{x}}+{\frac {\partial \tau _{r_{x}}}{\partial r}}dr\right)2\pi (r+dr)dx-\tau _{r_{x}}2\pi rdx}

=

τ

r

x

2

π

r

d

x

+

τ

r

x

2

π

d

r

d

x

+

(

∂

τ

r

x

∂

r

)

2

π

r

d

r

d

x

+

(

∂

τ

r

x

∂

r

)

2

π

r

d

r

2

d

x

⏟

d

r

2

≈

0

−

τ

r

x

2

π

r

d

x

{\displaystyle =\tau _{r_{x}}2\pi rdx+\tau _{r_{x}}2\pi drdx+\left({\frac {\partial \tau _{r_{x}}}{\partial r}}\right)2\pi rdrdx+\underbrace {\left({\frac {\partial \tau _{r_{x}}}{\partial r}}\right)2\pi r{dr}^{2}dx} _{{dr}^{2}\approx 0}-\tau _{r_{x}}2\pi rdx}

→

τ

r

x

2

π

d

r

d

x

+

(

∂

τ

r

x

∂

r

)

2

π

r

d

r

d

x

{\displaystyle \rightarrow \tau _{r_{x}}2\pi drdx+\left({\frac {\partial \tau _{r_{x}}}{\partial r}}\right)2\pi rdrdx}

−

(

∂

P

∂

x

)

2

π

r

d

r

d

x

+

τ

r

x

2

π

d

r

d

x

+

(

∂

τ

r

x

∂

r

)

2

π

r

d

r

d

x

=

0

{\displaystyle -\left({\frac {\partial P}{\partial x}}\right)2\pi rdrdx+\tau _{r_{x}}2\pi drdx+\left({\frac {\partial \tau _{r_{x}}}{\partial r}}\right)2\pi rdrdx=0}

it could be rewritten as

−

(

∂

P

∂

x

)

2

π

r

d

r

d

x

+

(

τ

r

x

+

r

∂

τ

r

x

∂

r

)

2

π

d

r

d

x

=

0

{\displaystyle -\left({\frac {\partial P}{\partial x}}\right)2\pi rdrdx+(\tau _{r_{x}}+r{\frac {\partial \tau _{r_{x}}}{\partial r}})2\pi drdx=0}

dividing both side with

2

π

d

r

d

x

{\displaystyle 2\pi drdx}

−

(

∂

P

∂

x

)

r

+

∂

(

r

τ

r

x

)

∂

r

=

0

{\displaystyle -\left({\frac {\partial P}{\partial x}}\right)r+{\frac {\partial (r\tau _{r_{x}})}{\partial r}}=0}

or,

(

∂

P

∂

x

)

r

=

∂

(

r

τ

r

x

)

∂

r

{\displaystyle \left({\frac {\partial P}{\partial x}}\right)r={\frac {\partial (r\tau _{r_{x}})}{\partial r}}}

integrating both side ,

∫

(

∂

P

∂

x

)

r

d

r

=

∫

∂

(

r

τ

r

x

)

{\displaystyle \int \left({\frac {\partial P}{\partial x}}\right)r\,dr=\int \partial (r\tau _{r_{x}})}

or,

(

∂

P

∂

x

)

r

2

2

=

r

τ

r

x

{\displaystyle \left({\frac {\partial P}{\partial x}}\right){\frac {r^{2}}{2}}=r\tau _{r_{x}}}

or,

(

∂

P

∂

x

)

r

2

=

τ

r

x

{\displaystyle \left({\frac {\partial P}{\partial x}}\right){\frac {r}{2}}=\tau _{r_{x}}}

However,in a laminar flow!

μ

d

U

d

r

=

1

2

r

∂

P

∂

x

{\displaystyle \mu {\frac {dU}{dr}}={\frac {1}{2}}r{\frac {\partial P}{\partial x}}}

U

=

r

2

4

μ

(

∂

P

∂

x

)

+

c

1

{\displaystyle U={\frac {r^{2}}{4\mu }}\left({\frac {\partial P}{\partial x}}\right)+c_{1}}

U

=

0

a

t

r

=

R

{\displaystyle U=0\ at\ r=R}

c

1

{\displaystyle c_{1}}

c

1

=

−

R

2

4

μ

(

∂

P

∂

x

)

⇒

U

=

1

4

μ

(

∂

P

∂

x

)

(

r

2

−

R

2

)

{\displaystyle c_{1}=-{\frac {R^{2}}{4\mu }}\left({\frac {\partial P}{\partial x}}\right)\Rightarrow U={\frac {1}{4\mu }}\left({\frac {\partial P}{\partial x}}\right)(r^{2}-R^{2})}

U

=

−

R

2

4

μ

(

∂

P

∂

x

)

[

1

−

(

r

R

)

2

]

{\displaystyle U=-{\frac {R^{2}}{4\mu }}\left({\frac {\partial P}{\partial x}}\right)\left[1-\left({\frac {r}{R}}\right)^{2}\right]}

(iii) Using NS in cylindrical co-ordinates:

x

:

ρ

(

∂

u

x

∂

t

⏟

s

t

e

a

d

y

s

t

a

t

e

+

u

r

∂

u

x

∂

r

⏟

u

r

=

0

+

u

ϕ

r

∂

u

x

∂

ϕ

⏟

u

ϕ

=

0

+

u

x

∂

u

x

∂

x

⏟

∂

u

x

∂

x

=

0

)

=

−

∂

p

∂

x

+

μ

[

1

r

∂

∂

r

(

r

∂

u

x

∂

r

)

+

1

r

2

∂

2

u

x

∂

ϕ

2

⏟

=

0

+

∂

2

u

x

∂

x

2

⏟

=

0

]

+

ρ

g

x

⏟

g

x

=

0

{\displaystyle x:\rho \left(\underbrace {\frac {\partial u_{x}}{\partial t}} _{steadystate}+\underbrace {u_{r}{\frac {\partial u_{x}}{\partial r}}} _{u_{r}=0}+\underbrace {{\frac {u_{\phi }}{r}}{\frac {\partial u_{x}}{\partial \phi }}} _{u_{\phi }=0}+\underbrace {u_{x}{\frac {\partial u_{x}}{\partial x}}} _{{\frac {\partial u_{x}}{\partial x}}=0}\right)=-{\frac {\partial p}{\partial x}}+\mu \left[{\frac {1}{r}}{\frac {\partial }{\partial r}}\left(r{\frac {\partial u_{x}}{\partial r}}\right)+\underbrace {{\frac {1}{r^{2}}}{\frac {\partial ^{2}u_{x}}{\partial \phi ^{2}}}} _{=0}+\underbrace {\frac {\partial ^{2}u_{x}}{\partial x^{2}}} _{=0}\right]+\underbrace {\rho g_{x}} _{g_{x}=0}}

thus,

∂

p

∂

x

=

μ

[

1

r

∂

∂

r

(

r

∂

u

x

∂

r

)

]

{\displaystyle {\frac {\partial p}{\partial x}}=\mu \left[{\frac {1}{r}}{\frac {\partial }{\partial r}}\left(r{\frac {\partial u_{x}}{\partial r}}\right)\right]}

or,

∂

p

∂

x

=

μ

r

[

∂

∂

r

(

r

∂

u

x

∂

r

)

]

{\displaystyle {\frac {\partial p}{\partial x}}={\frac {\mu }{r}}\left[{\frac {\partial }{\partial r}}\left(r{\frac {\partial u_{x}}{\partial r}}\right)\right]}

or,

(

∂

p

∂

x

)

r

μ

=

[

∂

∂

r

(

r

∂

u

x

∂

r

)

]

{\displaystyle \left({\frac {\partial p}{\partial x}}\right){\frac {r}{\mu }}=\left[{\frac {\partial }{\partial r}}\left(r{\frac {\partial u_{x}}{\partial r}}\right)\right]}

Now, integrating both side with respect to

r

{\displaystyle r}

∫

(

∂

p

∂

x

)

r

μ

d

r

=

∫

∂

(

r

∂

u

x

∂

r

)

{\displaystyle \int \left({\frac {\partial p}{\partial x}}\right){\frac {r}{\mu }}dr=\int \partial \left(r{\frac {\partial u_{x}}{\partial r}}\right)}

then,

(

∂

p

∂

x

)

r

2

2

μ

+

C

=

(

r

∂

u

x

∂

r

)

{\displaystyle \left({\frac {\partial p}{\partial x}}\right){\frac {r^{2}}{2\mu }}+C=\left(r{\frac {\partial u_{x}}{\partial r}}\right)}

dividing by r in both side , we get then

(

∂

p

∂

x

)

r

2

μ

+

C

r

=

(

∂

u

x

∂

r

)

{\displaystyle \left({\frac {\partial p}{\partial x}}\right){\frac {r}{2\mu }}+{\frac {C}{r}}=\left({\frac {\partial u_{x}}{\partial r}}\right)}

integrating again with respect to

r

{\displaystyle r}

(

∂

p

∂

x

)

r

2

4

μ

+

C

ln

r

+

D

=

U

x

(

r

)

{\displaystyle \left({\frac {\partial p}{\partial x}}\right){\frac {r^{2}}{4\mu }}+C\ln r+D=U_{x}(r)}

Consequently, when

r

=

0

{\displaystyle r=0}

U

x

=

U

m

a

x

{\displaystyle U_{x}=U_{max}}

ln

r

=

∞

{\displaystyle \ln r=\infty }

On the other hand, when

r

=

R

{\displaystyle r=R}

U

x

=

0

{\displaystyle U_{x}=0}

(

∂

p

∂

x

)

R

2

4

μ

+

D

=

0

{\displaystyle \left({\frac {\partial p}{\partial x}}\right){\frac {R^{2}}{4\mu }}+D=0}

or,

D

=

−

(

∂

p

∂

x

)

R

2

4

μ

{\displaystyle D=-\left({\frac {\partial p}{\partial x}}\right){\frac {R^{2}}{4\mu }}}

By putting D to the primitive equation, we get,

U

=

−

R

2

4

μ

(

∂

P

∂

x

)

[

1

−

(

r

R

)

2

]

{\displaystyle U=-{\frac {R^{2}}{4\mu }}\left({\frac {\partial P}{\partial x}}\right)\left[1-\left({\frac {r}{R}}\right)^{2}\right]}

τ

r

x

=

μ

d

U

d

r

=

r

2

(

∂

P

∂

x

)

{\displaystyle \tau _{r_{x}}=\mu {\frac {dU}{dr}}={\frac {r}{2}}\left({\frac {\partial P}{\partial x}}\right)}

→

τ

r

x

=

0

{\displaystyle \rightarrow \tau _{r_{x}}=0}

at r = R

→

τ

r

x

=

R

2

(

∂

P

∂

x

)

{\displaystyle \rightarrow \tau _{r_{x}}={\frac {R}{2}}\left({\frac {\partial P}{\partial x}}\right)}

Shear stress distribution in the fully developed laminar pipe flow. The volume flow rate would read

Q

=

∫

A

r

e

a

U

i

n

i

d

A

=

∫

A

r

e

a

U

2

π

r

d

r

{\displaystyle \displaystyle Q=\int _{Area}U_{i}n_{i}dA=\int _{Area}U2\pi rdr}

Q

=

∫

1

4

μ

(

∂

P

∂

x

)

(

r

2

−

R

2

)

2

π

r

d

r

{\displaystyle Q=\int {\frac {1}{4\mu }}\left({\frac {\partial P}{\partial x}}\right)(r^{2}-R^{2})2\pi rdr}

Q

=

−

π

R

4

8

μ

(

∂

P

∂

x

)

{\displaystyle Q=-{\frac {\pi R^{4}}{8\mu }}\left({\frac {\partial P}{\partial x}}\right)}

∂

P

∂

x

=

−

Δ

P

L

{\displaystyle {\frac {\partial P}{\partial x}}=-{\frac {\Delta P}{L}}}

Q

=

−

π

R

4

8

μ

[

−

Δ

P

L

]

=

π

Δ

P

R

4

8

μ

L

=

π

Δ

P

D

4

128

μ

L

{\displaystyle Q=-{\frac {\pi R^{4}}{8\mu }}\left[{\frac {-\Delta P}{L}}\right]={\frac {\pi \Delta PR^{4}}{8\mu L}}={\frac {\pi \Delta PD^{4}}{128\mu L}}}

Δ

P

=

128

μ

L

π

D

4

Q

{\displaystyle \Delta P={\frac {128\mu L}{\pi D^{4}}}Q}

The mean velocity is:

U

¯

=

Q

A

=

Q

π

R

2

=

−

R

2

8

μ

(

∂

P

∂

x

)

=

−

D

2

32

μ

(

∂

P

∂

x

)

{\displaystyle {\bar {U}}={\frac {Q}{A}}={\frac {Q}{\pi R^{2}}}={\frac {-R^{2}}{8\mu }}\left({\frac {\partial P}{\partial x}}\right)=-{\frac {D^{2}}{32\mu }}\left({\frac {\partial P}{\partial x}}\right)}

d

U

d

r

=

0

→

d

U

d

r

=

1

2

μ

(

∂

P

∂

x

)

r

{\displaystyle {\frac {dU}{dr}}=0\rightarrow {\frac {dU}{dr}}={\frac {1}{2\mu }}\left({\frac {\partial P}{\partial x}}\right)r}

→

{\displaystyle \rightarrow }

U

m

a

x

{\displaystyle U_{max}}

U

m

a

x

=

U

(

0

)

=

−

R

2

4

μ

(

∂

P

∂

x

)

=

2

U

¯

{\displaystyle U_{max}=U(0)=-{\frac {R^{2}}{4\mu }}\left({\frac {\partial P}{\partial x}}\right)=2{\bar {U}}}

U

m

a

x

=

3

2

U

¯

{\displaystyle U_{max}={\frac {3}{2}}{\bar {U}}}

U

{\displaystyle U}

U

m

a

x

{\displaystyle U_{max}}

U

=

−

R

2

4

μ

(

∂

P

∂

x

)

⏟

U

m

a

x

[

1

−

(

r

R

)

2

]

{\displaystyle U=\underbrace {-{\frac {R^{2}}{4\mu }}\left({\frac {\partial P}{\partial x}}\right)} _{U_{max}}\left[1-\left({\frac {r}{R}}\right)^{2}\right]}

U

U

m

a

x

=

[

1

−

(

r

R

)

2

]

{\displaystyle {\frac {U}{U_{max}}}=\left[1-\left({\frac {r}{R}}\right)^{2}\right]}

↑ Fox, R.W. and McDonald, A.T., “Introduction to Fluid Mechanics”, John Willey and Sons.

↑ M. Nishi. PhD Thesis Friedrich-Alexander-Universität Erlangen-Nürnberg, 2009.

↑ M. Nishi, B. Ünsal, F. Durst, and G. Biswas. J. Fluid Mech., 614:425–446, 2008.

↑ Durst, F., Ray, S., Unsal, B., and Bayoumi, O. A., 2005, “The Development Lengths of Laminar Pipe and Channel Flows,” J. Fluids Eng., 127, pp. 1154– 1160.

↑ Acheson, D.J.: Elementary fluid dynamics, Clarendon Press, 1990.

![{\displaystyle {\frac {Le_{pipe}}{D}}=\left[(0.619)^{1.6}+(0.0567Re)^{1.6}\right]^{\frac {1}{1.6}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/c09c2fb3669cbeac03e159d28dece35208bd89bd)

![{\displaystyle {\frac {Le_{channel}}{D}}=\left[(0.631)^{1.6}+(0.0442Re)^{1.6}\right]^{\frac {1}{1.6}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/9b2a412a03c272a1209d0be4c24b6d541d3b27d5)

![{\displaystyle \rho U_{i}{\frac {\partial U_{1}}{\partial x_{i}}}=\rho \left[U_{1}\underbrace {\frac {\partial U_{1}}{\partial x_{1}}} _{=0\ Fully-developed}+\underbrace {U_{2}} _{=0}{\frac {\partial U_{1}}{\partial x_{2}}}+\underbrace {U_{3}} _{=0\ fully-developed\ 2D}\underbrace {\frac {\partial U_{1}}{\partial x_{3}}} _{=0\ 2D}\right]=0}](https://wikimedia.org/api/rest_v1/media/math/render/svg/2729b54766bf0de2e4e70e19a6508a90833ffad1)

![{\displaystyle {\begin{array}{lll}U_{1}&=&{\frac {1}{2\mu }}\left({\frac {\partial P}{\partial x_{1}}}x_{2}^{2}\right)-{\frac {1}{2\mu }}\left({\frac {\partial P}{\partial x_{1}}}\right)D{x_{2}}\\&=&{\frac {D^{2}}{2\mu }}\left({\frac {\partial P}{\partial x_{1}}}\right)\left[\left({\frac {x_{2}}{D}}\right)^{2}-\left({\frac {x_{2}}{D}}\right)\right]\end{array}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/c313de955e440458ac6f604b0d631ddd35cb2eb5)

![{\displaystyle {\begin{array}{lll}\tau _{21}&=&\left({\frac {\partial P}{\partial x_{1}}}\right)x_{2}-{\frac {1}{2}}\left({\frac {\partial P}{\partial x_{1}}}\right)D\\&=&D\left({\frac {\partial P}{\partial x_{1}}}\right)\left[{\frac {x_{2}}{D}}-{\frac {1}{2}}\right]\end{array}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/6d01cb1d9fefd03f413e7cd689ea9bd3ec25ad0c)

![{\displaystyle {\begin{array}{lll}U_{1}&=&-4U_{1max}\left[\left({\frac {x_{2}}{D}}\right)^{2}-\left({\frac {x_{2}}{D}}\right)\right]\\&=&-6{\overline {U}}\left[\left({\frac {x_{2}}{D}}\right)^{2}-\left({\frac {x_{2}}{D}}\right)\right]\end{array}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/c7d1616d3bac46187b4c138275e9974251571d3a)

![{\displaystyle U_{1}^{A}=-{\frac {D^{2}}{2\mu _{A}}}{\frac {d\Pi }{dx_{1}}}\left[+{\frac {2\mu _{A}}{(\mu _{A}+\mu _{B})}}+\left({\frac {\mu _{A}-\mu _{B}}{\mu _{A}+\mu _{B}}}\right)\left({\frac {x_{2}}{D}}\right)-\left({\frac {x_{2}}{D}}\right)^{2}\right]\ \ \ \ \ }](https://wikimedia.org/api/rest_v1/media/math/render/svg/c7435790d355056f4bce40710ea65b903145ced7)

![{\displaystyle U_{1}^{B}=-{\frac {D^{2}}{2\mu _{B}}}{\frac {d\Pi }{dx_{1}}}\left[+{\frac {2\mu _{B}}{(\mu _{A}+\mu _{B})}}+\left({\frac {\mu _{A}-\mu _{B}}{\mu _{A}+\mu _{B}}}\right)\left({\frac {x_{2}}{D}}\right)-\left({\frac {x_{2}}{D}}\right)^{2}\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/14221c95f3d4824170689e20cea5ddaf028454fe)

![{\displaystyle \tau _{21}=D{\frac {d\Pi }{dx_{1}}}\left[\left({\frac {x_{2}}{D}}\right)-{\frac {1}{2}}\left({\frac {\mu _{A}-\mu _{B}}{\mu _{A}+\mu _{B}}}\right)\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/c7b7bd2ece16a741add08efed717f6a2f25654ad)

![{\displaystyle U_{1}={\frac {-D^{2}}{2\mu _{A}}}{\frac {d\Pi }{dx_{1}}}\left[1-\left({\frac {x_{2}}{D}}\right)^{2}\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/e0aeab4a5851025d33c41bcc1f6e05eb86da0973)

![{\displaystyle \tau _{W}^{B}={\frac {D}{2}}{\frac {d\Pi }{dx_{1}}}\left[{\frac {\mu _{A}+3\mu _{B}}{\mu _{A}+\mu _{B}}}\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/0af490f764cb72897feb5154542c2febb8b7eb92)

![{\displaystyle \tau _{W}^{A}=-{\frac {D}{2}}{\frac {d\Pi }{dx_{1}}}\left[{\frac {3\mu _{A}+\mu _{B}}{\mu _{A}+\mu _{B}}}\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/5370761d08a3c12a7bcf6545e641b382c59a2244)

![{\displaystyle r:\;\;\rho \left({\frac {\partial u_{r}}{\partial t}}+u_{r}{\frac {\partial u_{r}}{\partial r}}+{\frac {u_{\phi }}{r}}{\frac {\partial u_{r}}{\partial \phi }}+u_{x}{\frac {\partial u_{r}}{\partial x}}-{\frac {u_{\phi }^{2}}{r}}\right)=-{\frac {\partial p}{\partial r}}+\mu \left[{\frac {1}{r}}{\frac {\partial }{\partial r}}\left(r{\frac {\partial u_{r}}{\partial r}}\right)+{\frac {1}{r^{2}}}{\frac {\partial ^{2}u_{r}}{\partial \phi ^{2}}}+{\frac {\partial ^{2}u_{r}}{\partial x^{2}}}-{\frac {u_{r}}{r^{2}}}-{\frac {2}{r^{2}}}{\frac {\partial u_{\phi }}{\partial \phi }}\right]+\rho g_{r}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/79665b986fbf4bd84a218d083f4a700dc7f5341b)

![{\displaystyle \phi :\;\;\rho \left({\frac {\partial u_{\phi }}{\partial t}}+u_{r}{\frac {\partial u_{\phi }}{\partial r}}+{\frac {u_{\phi }}{r}}{\frac {\partial u_{\phi }}{\partial \phi }}+u_{x}{\frac {\partial u_{\phi }}{\partial x}}+{\frac {u_{r}u_{\phi }}{r}}\right)=-{\frac {1}{r}}{\frac {\partial p}{\partial \phi }}+\mu \left[{\frac {1}{r}}{\frac {\partial }{\partial r}}\left(r{\frac {\partial u_{\phi }}{\partial r}}\right)+{\frac {1}{r^{2}}}{\frac {\partial ^{2}u_{\phi }}{\partial \phi ^{2}}}+{\frac {\partial ^{2}u_{\phi }}{\partial z^{2}}}+{\frac {2}{r^{2}}}{\frac {\partial u_{r}}{\partial \phi }}-{\frac {u_{\phi }}{r^{2}}}\right]+\rho g_{\phi }}](https://wikimedia.org/api/rest_v1/media/math/render/svg/eab5ccaa957c10c01022b6944324dfaf2509829c)

![{\displaystyle x:\;\;\rho \left({\frac {\partial u_{x}}{\partial t}}+u_{r}{\frac {\partial u_{x}}{\partial r}}+{\frac {u_{\phi }}{r}}{\frac {\partial u_{x}}{\partial \phi }}+u_{x}{\frac {\partial u_{x}}{\partial x}}\right)=-{\frac {\partial p}{\partial x}}+\mu \left[{\frac {1}{r}}{\frac {\partial }{\partial r}}\left(r{\frac {\partial u_{x}}{\partial r}}\right)+{\frac {1}{r^{2}}}{\frac {\partial ^{2}u_{x}}{\partial \phi ^{2}}}+{\frac {\partial ^{2}u_{x}}{\partial x^{2}}}\right]+\rho g_{x}.}](https://wikimedia.org/api/rest_v1/media/math/render/svg/6f30e155efe946e29f5b3b84f90fe40f8a4d9cd0)

![{\displaystyle U=-{\frac {R^{2}}{4\mu }}\left({\frac {\partial P}{\partial x}}\right)\left[1-\left({\frac {r}{R}}\right)^{2}\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/c3162e988bb3748f482bb062791ad3a45d0e06c0)

![{\displaystyle x:\rho \left(\underbrace {\frac {\partial u_{x}}{\partial t}} _{steadystate}+\underbrace {u_{r}{\frac {\partial u_{x}}{\partial r}}} _{u_{r}=0}+\underbrace {{\frac {u_{\phi }}{r}}{\frac {\partial u_{x}}{\partial \phi }}} _{u_{\phi }=0}+\underbrace {u_{x}{\frac {\partial u_{x}}{\partial x}}} _{{\frac {\partial u_{x}}{\partial x}}=0}\right)=-{\frac {\partial p}{\partial x}}+\mu \left[{\frac {1}{r}}{\frac {\partial }{\partial r}}\left(r{\frac {\partial u_{x}}{\partial r}}\right)+\underbrace {{\frac {1}{r^{2}}}{\frac {\partial ^{2}u_{x}}{\partial \phi ^{2}}}} _{=0}+\underbrace {\frac {\partial ^{2}u_{x}}{\partial x^{2}}} _{=0}\right]+\underbrace {\rho g_{x}} _{g_{x}=0}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/4169e94a5642a56f1a6e420091ce4898082dde05)

![{\displaystyle {\frac {\partial p}{\partial x}}=\mu \left[{\frac {1}{r}}{\frac {\partial }{\partial r}}\left(r{\frac {\partial u_{x}}{\partial r}}\right)\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/336a1949e2b64456650c71e8ee3722bebf2f3a7a)

![{\displaystyle {\frac {\partial p}{\partial x}}={\frac {\mu }{r}}\left[{\frac {\partial }{\partial r}}\left(r{\frac {\partial u_{x}}{\partial r}}\right)\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/65b1953e4815430ccb32db9fa16b0050dfd0f836)

![{\displaystyle \left({\frac {\partial p}{\partial x}}\right){\frac {r}{\mu }}=\left[{\frac {\partial }{\partial r}}\left(r{\frac {\partial u_{x}}{\partial r}}\right)\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/0695f3a62f7a8e14a003e24d6e70799446d70ced)

![{\displaystyle Q=-{\frac {\pi R^{4}}{8\mu }}\left[{\frac {-\Delta P}{L}}\right]={\frac {\pi \Delta PR^{4}}{8\mu L}}={\frac {\pi \Delta PD^{4}}{128\mu L}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/3de87eb15d32a69c1e316bf03b37d3d2de6ae85f)

![{\displaystyle U=\underbrace {-{\frac {R^{2}}{4\mu }}\left({\frac {\partial P}{\partial x}}\right)} _{U_{max}}\left[1-\left({\frac {r}{R}}\right)^{2}\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/bd50358dbba0ccb8a8f4221225f9e8dede4d641a)

![{\displaystyle {\frac {U}{U_{max}}}=\left[1-\left({\frac {r}{R}}\right)^{2}\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/c9f03eb32b729ed8832b4ef7c42ef64e45d519dd)