Automotive Technology/Suspension and Steering

This page is written for those taking the ASE A4 test

- Always mark the placement of any part before removal

Steering

[edit | edit source]Always disable the Air Bag system before any change to the steering column.

Steering Columns should be locked into place to preserve timing and prevent overextending the clock-spring.

Replace Bushings when they no longer hold the part in position. Replace Bearings when they have any visible play, or have a turning torque outside of specification.

Adjustments can affect front wheel toe

Diagnosis

[edit | edit source]Bump steer can be caused by

- Loose idler arm

- Loose rack mountings

- Loose or damaged mounting

Steering wheel free play can be caused by

- Worn couplings

- worn u joint

- Loose mounting

Steering problems are sometimes subframe alignment problems

Manual Steering Gears

[edit | edit source]Also known as worm gears

Noises, binding, looseness, hard steering point to bearing and lubrication problems.

Rack and Pinion Steering Gear

[edit | edit source]Other parts

[edit | edit source]Air bag Steering wheel Clock spring

Worm gear Idler arm Rack and pinion

Tie rods

Power Steering Units

[edit | edit source]Power steering uses hydraulic pressure to apply force to the worm gear or rack

Diagnosis

[edit | edit source]Weeping, or a slight fluid leak requires repair or replacement

- inspect power steering fluid

- Remove and replace power steering pump belt, tensioner, pulley

- diagnose power steering pump problems

- Remove and replace power steering pump

- power steering pressure testio

- Remove and replace power steering hydraulics

- Steering gear worm bearing preload and sector lash

- Remove and replace steering gear seals and gaskets

- Remove and replace rack and pinion unit

- Remove and replace rack and pinion steering gear bellows/boots.

- flush, fill, bleed power steering hydraulics

- Diagnose, Remove and replace variable-assist steering systems

- Rack and Pinion Steering

- can provide assistance by applying pressure to one side

Steering Linkage

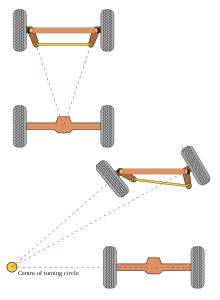

[edit | edit source]- Inspect and adjust steering linkage geometry

Pitman arm

[edit | edit source]Pitman arm is only bent in collisions, and wears on other parts. These are pressed on, and are difficult to separate from the splines.

Center link

[edit | edit source]If bent, will affect front wheel toe

Idler arm

[edit | edit source]- Remove and Replace tie rods

- Remove and Replace steering linkage damper

Remove and Replace

Suspension

[edit | edit source]

Front Suspension

[edit | edit source]Rear Suspension

[edit | edit source]Alignment

[edit | edit source]Frame

[edit | edit source]Springs

[edit | edit source]You should understand spring frequency, even if you never measure the frequency of the spring. Most spring are made of a chrome-vanadium alloy. Very tough stuff.

- Constant-velocity joint

- Usable in torque transfer

Suspension

[edit | edit source]ASE Task List

[edit | edit source]Glossary

[edit | edit source]- Aspect ratio

- Bead

- The lip of the tire that seals the rim flange

- Belt

- Material under the tread

- Center section AKA Spider

- Center of a steel wheel

- Conicity

- DOT tire code

- E-metric tire

- High flotation tire

- Inner liner

- Load index

- Lug nuts

- Major splice

- Offset

- Ply steer

- Rim width

- Run-flat

- Sidewall

- Speed rating

- TPC

- Unsprung Weight

- Weight below the spring in a vehicle

- Uniform Tire Quality Grading System (UTQG)

- Tires sold in the USA are rated in Tread wear, Traction, and Temperature Resistance as per NHTSA.

- Wear bars

- raised features located at the bottom of the tread grooves that indicate the tire has reached its wear limit